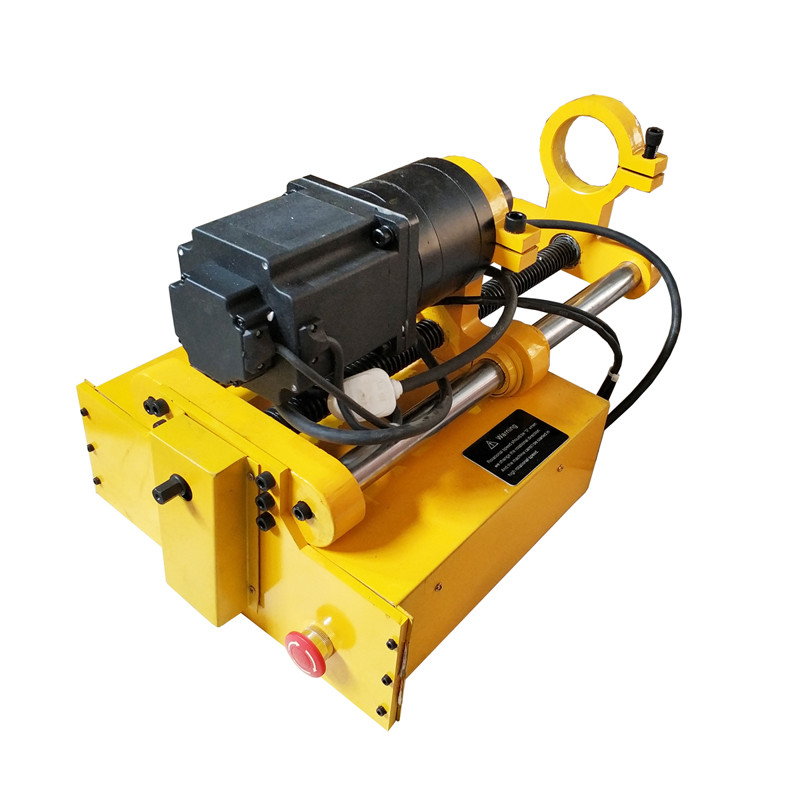

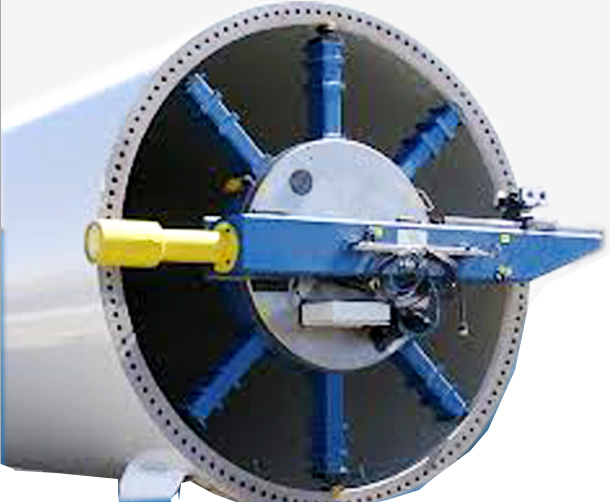

T60 portable line boring machine

T60 portable line boring machine are mobile welding and lathes that

can be used to carry out repairs directly on site using automatic /

mechanized build-up welding

and subsequent processing with one and the same machine, simply by

exchanging tools, bores or shafts (from 30 to 200 mm in diameter).

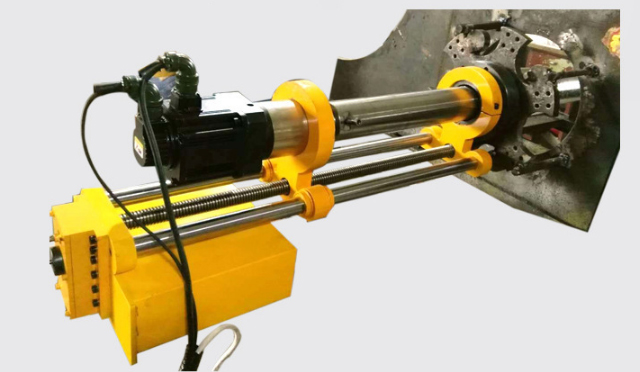

The T60 is attached to the defective device (excavator, crane, wheel

loader, caterpillar, crusher, etc.)

usually without major dismantling of the defective parts and without any

special knowledge on the part of the user and then by one or more

build-up welds

and subsequent machining Machining again with 100% safety in alignment

and repaired to the original size,

which has an effect on a much longer service life (⅓) of the very

cost-intensive bolts and bushings.

T60 portable line boring machine is a versatile and modular mobile line

boring machine, With the help of our mobile boring machine, rattling,

worn-out pin bearing points as well as worn, no longer perfectly fitting

bores for plain bearing bushes or roller and joint bearings can be

repaired.

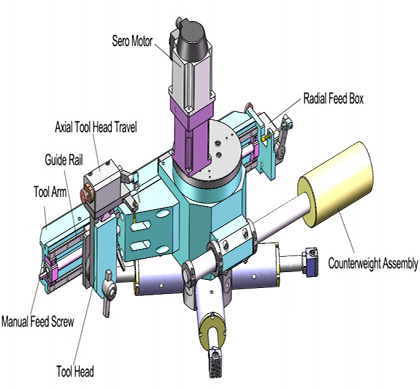

Technical specifications

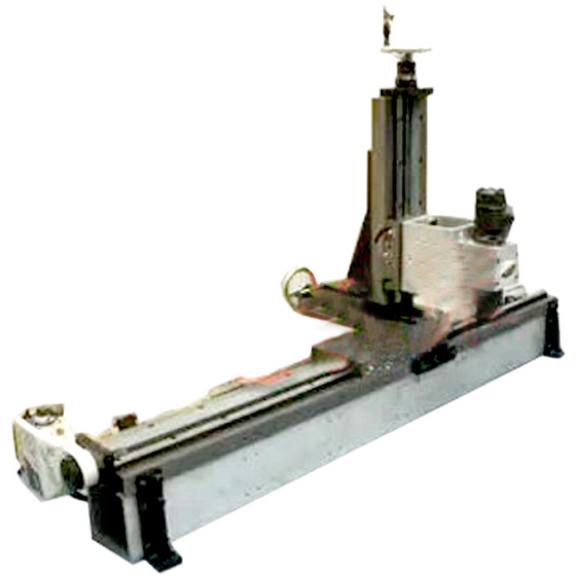

Weight: 23.5 kg

Dimensions: 820 × 300 × 300 (L × W × D)

The housing, gear block and machine box are made of AlZn5Mg3Cu, a

material used in aerospace engineering.

All mechanically stressed components exposed to wear, such as quill,

boring bar, etc. are made of high-quality steel, surface hardened and

precision ground.

For work in the diameter range: from 30 to 200 mm (with extension 300

mm)

with addition also bigger.

Boring bars: diameter / length 45 × 780 mm, 32 × 460 mm, 20 × 500 mm

The boring bars can be extended by a plug-in system.

The tool mounting holes on the boring bars with a diameter of 45 mm have

a diameter of 16 mm so that standard cutting tools can be used here.

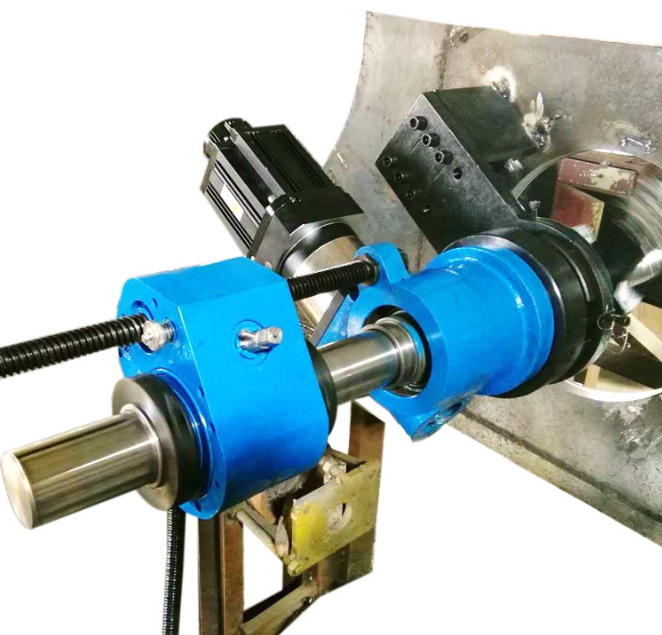

Motors: The rotary motor is a powerful 1600 W Duss electric motor with a

robust, mechanically switchable 4-stage gear. The speed of the motor is

infinitely variable from 0% to 99%,

electronically adjustable.

The feed motors are 24 V DC gear motors, the rapid feed motor is

equipped with a motor brake, which can also be electronically regulated

from 0% to 99%.

All motors are manufactured to the highest standards of quality,

reliability, durability and robustness, which is essential for the tough

and

tireless use of our T60 devices .

Working stroke: 250 mm stepless, electronically adjustable from 0-25 mm

/ min

Rapid feed: 1 m / min

Control: The control is not exposed to mechanical wear due to the

membrane keyboard and has the most modern components of the control

electronics (220 V / 50-60 Hz)

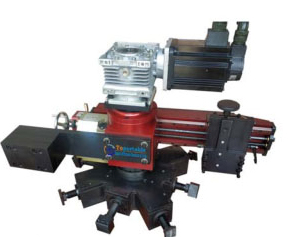

Burner: gas-cooled, 160 A

Welding device: any MIG / MAG welding machine

(recommended at 100% ED 140 A)

Hose package connection: EURO Standard / Binzel with a length of 3

meters

Rotation speed: The rotation speed of the welding head is electronically

adjustable from 0 to 5 rpm.

Welding feed: The welding feed is set at 3 mm / rev. The feed when

turning is infinitely variable and electronically adjustable.

The processing of blind holes must be carried out with an appropriate

adapter (accessory)!

|

Specifications & Accessories |

|

Standard Boring Bar (customizable) |

|

40*1500 mm (1.57*59 Inches) |

|

Boring Diameter |

|

45-200 mm

(1.77-7.87 Inches) |

|

Stroke |

|

390 mm (15.35 Inches) |

|

Feed Speed |

|

0-100(mm/min) |

|

Power Option |

| 1.5kw electric motor |