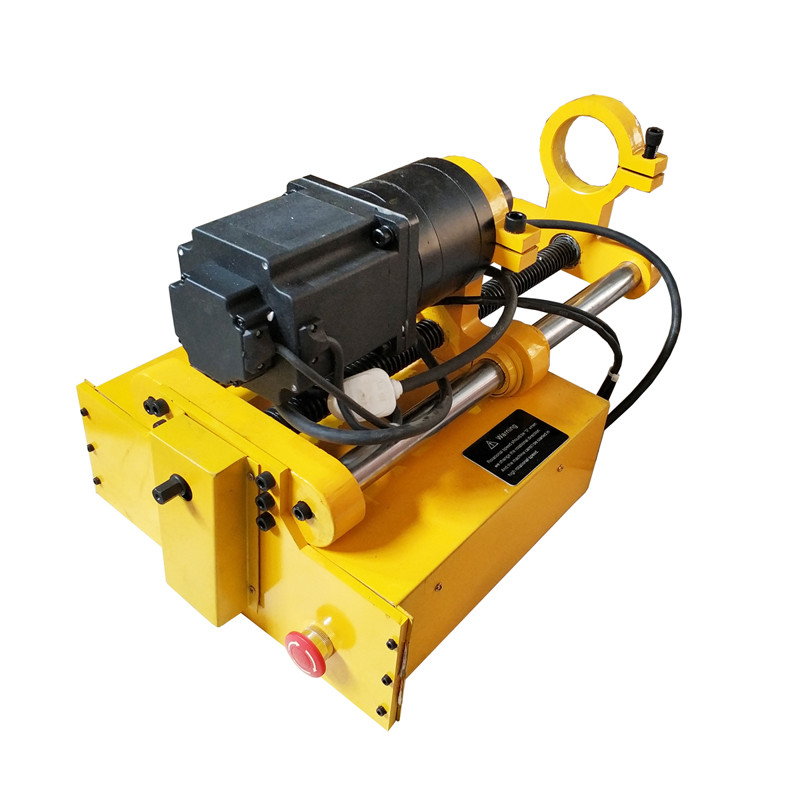

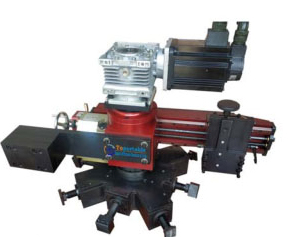

T50 portable line boring machine

T50 Mobile drilling and welding technology

With our mobile drilling and welding technology, it is possible for us

to repair worn-out bushing fits, bolt bearings and bores on site.

With build-up welding in the bore and mechanical processing, it is

possible to restore the original dimensions without major dismantling

work.

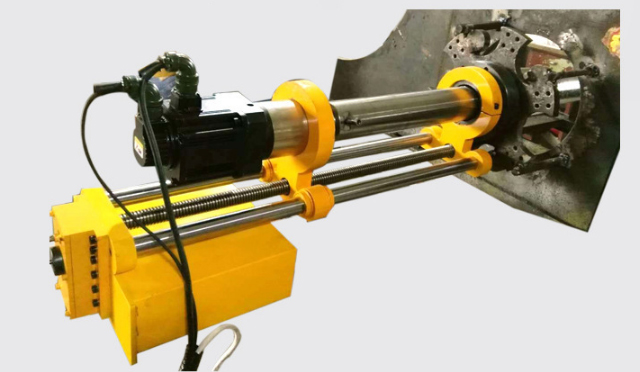

Complex and expensive transports of equipment parts are avoided because

the drilling can be done directly at the machine location.

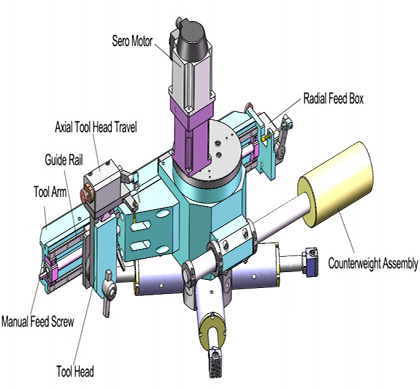

T50 portable line boring machine is a versatile and modular mobile line

boring machine, With the help of our mobile boring machine, rattling,

worn-out pin bearing points as well as worn, no longer perfectly fitting

bores for plain bearing bushes or roller and joint bearings can be

repaired.

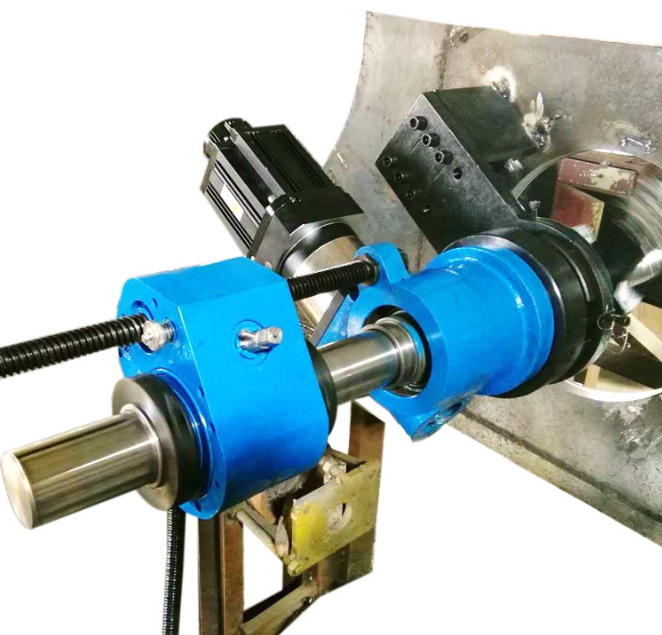

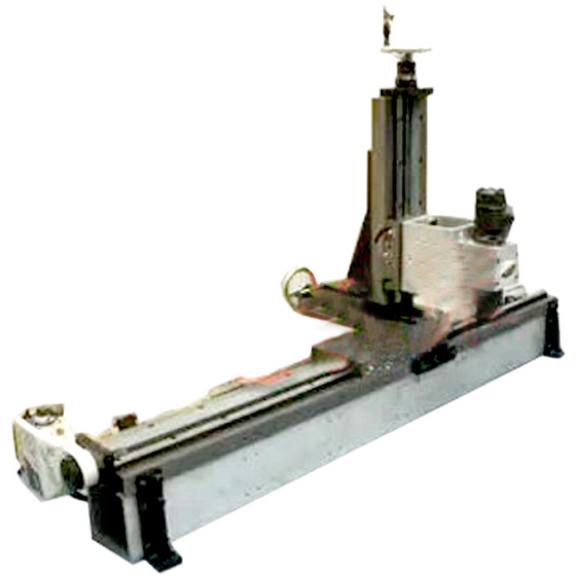

used for repairing buckets and booms of excavator, the loader arms and

bucket pin holes, etc. It’s a must-have tool to rebore holes round and

concentric again.

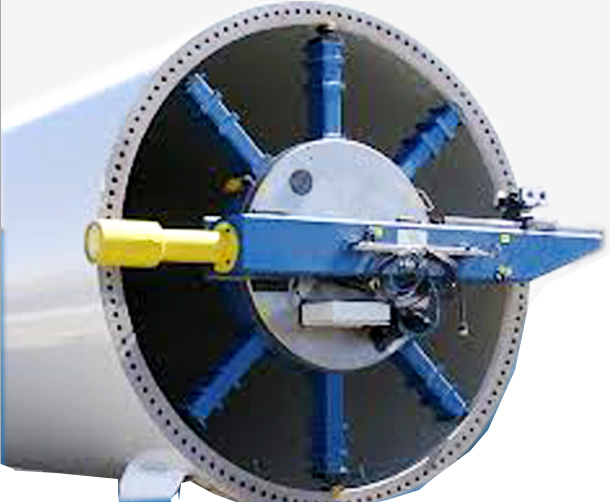

The mobile welding and drilling device enables repairs directly on the

construction site through automatic / mechanized build-up welding and

subsequent

processing with one and the same machine, by simply exchanging tools,

bores or shafts (diameter 55 to 260 mm). The system is attached to the

defective device (excavator, crane,

wheel loader, caterpillar, crusher, etc.) usually without great

dismantling of the defective parts and without special knowledge of the

user, directly on site,

then by one or more build-up welds and subsequent machining repaired..

|

Specifications & Accessories |

|

Standard Boring Bar (customizable) |

|

50*1500 mm (1.97*59 Inches) |

|

Boring Diameter |

|

55-260 mm

(2.17-10.4 Inches) |

|

Stroke |

|

390 mm (15.35 Inches) |

|

Feed Speed |

|

0-0.5mm/r (0-0.02 inches/r) |

|

Power Option |

| 3kw electric motor |